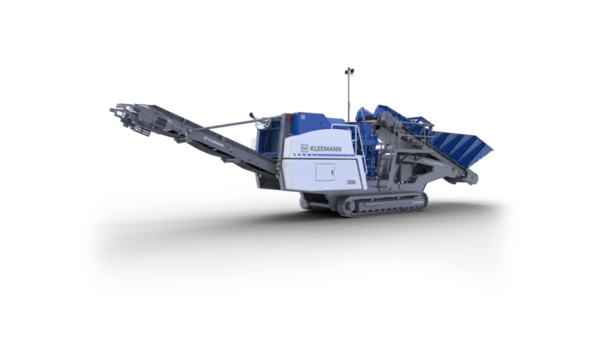

Kleemann MCO 9i EVO

| Make | Kleemann |

| Model | MCO 9i EVO |

| Type | Mobile Cone Crushers |

How can we help?

Description

Properties

The MOBICONE MCO 9i EVO has compact dimensions and, with a weight of 30 tons, transportation is straight-forward. Thanks to the easy setup, just a few steps are needed to set it up and prepare it for operation. Being compact and powerful, the plant also scores in terms of diesel consumption: The diesel direct drive and also the electric drives of the conveyor belts ensure that fuel consumption is pleasantly acceptable. The optional extended crusher discharge conveyor can be folded hydraulically as standard and enables a high stockpile volume.

-

Cone crusher with slide bearings and automatic circulation lubrication for high feed capacity and long service life

-

As secondary or tertiary crusher

-

Diesel direct drive

-

Can be linked with other KLEEMANN plants (option)

Models

Cone crusher

Cone crushers crush the feed material in a circulating opening and closing crushing gap between bowl liner and crusher cone. Opening and closing also takes place simultaneously on the opposites sides of the crushing chamber.

Innovative diesel-direct electric drive concept - impressive performance with the best possible consumption values

The crushers of the EVO line have an innovative "diesel-direct electric" drive concept and are powerful and economical at the same time.

An efficient and powerful diesel engine drives the crusher directly via a fluid coupling. The drive technology thus impresses with extremely low efficiency losses and maximum output directly at the crusher.

All secondary drives – for example, for prescreen, vibrating chutes and conveyor belts – are driven electrically. The fluid coupling guarantees high operational safety – for operator and machine.

Plant linkage for perfect combination versatility.

The line coupling option allows special KLEEMANN plants to be coupled with one another. The crushing process between the crushing plants is automatically controlled so that material is always conveyed with maximum efficiency through the machines.

A probe is installed at the crusher discharge conveyor of the upstream machine, which monitors the filling level of the feeding unit of the downstream machine. When the filling level reaches a defined height, the output of the upstream plant is temporarily reduced or feeding is switched off, thus effectively reducing the overfilling of individual machines and ensuring that machine utilization is always ideal. The feed control Continuous Feed System (CFS) also guarantees optimum utilization of the crusher.

For safety reasons, the crushing and screening plants are connected physically with one another by a cable. If an emergency stop button is pressed on the plant train in the event of an emergency, all machines are safely stopped.

Ring Bounce Detection

During ring bounce, a movement is created between the bowl and the main frame of the cone crusher as a result of excessive crushing forces. This is triggered by feed sizes that are too large or small, an excessive fine content or the continuous feeding of uncrushable material.

To protect the crusher, software continuously monitors the hydraulic pressure of the crusher overload system and reacts when necessary with two modes:

Mode 1 – PRECISE MODEfor the production of grit: The machine stops feeding if ring bounce is detected; the operator receives a fault message and can adapt his process. This mode assures that no impermissible oversize grain is produced and the machine is protected against crusher damage

Mode 2 – MIXTURE MODEfor the production of mixtures: In this mode, the machine adjusts the crushing gap - without intervention of the operator - automatically to prevent ring bounce. After a defined period without ring bounce, the gap is closed again to keep the share of oversize grain as low as possible

Continuous Feed System (CFS)

Uniform loading is indispensable for a good product, optimum throughput and low wear.

To ensure that the crushing chamber is always evenly filled, the Continuous Feed System (CFS) monitors the crusher level (jaw crusher and cone crusher) or the load at the rocker and rotor as well as the motor utilization (impact crusher).

Independently of this, the CFS regulates the frequency of the vibrating feeder and prescreen. A backlog on the prescreen is thus avoided and crusher utilization is optimized. When the crushing chamber is free again after overloading, material transport is continued without a delay.

The CFS facilitates the work of the operator because the machine automatically guarantees a homogeneous material flow, thus ensuring optimum loading of the crusher.

Specifications

- CRUSHER - Crusher capacity: 215 hp

- CRUSHER - Crusher drive type: direct

- CRUSHER - Crusher system size: 38 in

- CRUSHER - Crusher weight (approx.): 19,600 lbs

- CRUSHER DISCHARGE CONVEYOR - Crusher discharge conveyor length: 28 ft 10 in

- CRUSHER DISCHARGE CONVEYOR - Discharge height approx.: 10 ft 6 in

- CRUSHER DISCHARGE CONVEYOR - Discharge height, extended, approx.: 12 ft 6 in

- CRUSHER DISCHARGE CONVEYOR - Length, extended: 34 ft 1 in

- CRUSHER DISCHARGE CONVEYOR - Width: 31 in

- CRUSHING CAPACITY - Crushing capacity at 0-32 mm approx.: 242

- CRUSHING CAPACITY - Crushing capacity at 0-63 mm approx.: 298 US t/hr

- FEEDING CONVEYOR - Length: 20 ft 12 in

- FEEDING UNIT - Feed height: 8 ft 8 in

- FEEDING UNIT - Feed height with extension: 10 ft 1 in

- FEEDING UNIT - Hopper length: 11 ft 8 in

- FEEDING UNIT - Hopper length with extension: 12 ft 7 in

- FEEDING UNIT - Hopper volume: 8.4 yd³

- FEEDING UNIT - Hopper volume with extension: 9.8 yd³

- FEEDING UNIT - Hopper width: 8 ft 6 in

- FEEDING UNIT - Max. feed size: 8 in

- POWER SUPPLY UNIT - Drive concept: Diesel-direct

- POWER SUPPLY UNIT - Generator: 130 kVA

- POWER SUPPLY UNIT - Power supply unit output: 326 hp

- TRANSPORT - Transport height approx. (standard value): 11 ft 2 in

- TRANSPORT - Transport length approx.: 52 ft 11 in

- TRANSPORT - Transport weight max. configuration approx.: 73,050 lbs

- TRANSPORT - Transport weight of basic plant: 66,300 lbs

- TRANSPORT - Transport width approx.: 9 ft 10 in

Links

Copy Set

Cone crusher

Cone crushers crush the feed material in a circulating opening and closing crushing gap between bowl liner and crusher cone. Opening and closing also takes place simultaneously on the opposites sides of the crushing chamber.

Innovative diesel-direct electric drive concept - impressive performance with the best possible consumption values

The crushers of the EVO line have an innovative "diesel-direct electric" drive concept and are powerful and economical at the same time.

An efficient and powerful diesel engine drives the crusher directly via a fluid coupling. The drive technology thus impresses with extremely low efficiency losses and maximum output directly at the crusher.

All secondary drives – for example, for prescreen, vibrating chutes and conveyor belts – are driven electrically. The fluid coupling guarantees high operational safety – for operator and machine.

Plant linkage for perfect combination versatility.

The line coupling option allows special KLEEMANN plants to be coupled with one another. The crushing process between the crushing plants is automatically controlled so that material is always conveyed with maximum efficiency through the machines.

A probe is installed at the crusher discharge conveyor of the upstream machine, which monitors the filling level of the feeding unit of the downstream machine. When the filling level reaches a defined height, the output of the upstream plant is temporarily reduced or feeding is switched off, thus effectively reducing the overfilling of individual machines and ensuring that machine utilization is always ideal. The feed control Continuous Feed System (CFS) also guarantees optimum utilization of the crusher.

For safety reasons, the crushing and screening plants are connected physically with one another by a cable. If an emergency stop button is pressed on the plant train in the event of an emergency, all machines are safely stopped.

Ring Bounce Detection

During ring bounce, a movement is created between the bowl and the main frame of the cone crusher as a result of excessive crushing forces. This is triggered by feed sizes that are too large or small, an excessive fine content or the continuous feeding of uncrushable material.

To protect the crusher, software continuously monitors the hydraulic pressure of the crusher overload system and reacts when necessary with two modes:

Mode 1 – PRECISE MODEfor the production of grit: The machine stops feeding if ring bounce is detected; the operator receives a fault message and can adapt his process. This mode assures that no impermissible oversize grain is produced and the machine is protected against crusher damage

Mode 2 – MIXTURE MODEfor the production of mixtures: In this mode, the machine adjusts the crushing gap - without intervention of the operator - automatically to prevent ring bounce. After a defined period without ring bounce, the gap is closed again to keep the share of oversize grain as low as possible

Continuous Feed System (CFS)

Uniform loading is indispensable for a good product, optimum throughput and low wear.

To ensure that the crushing chamber is always evenly filled, the Continuous Feed System (CFS) monitors the crusher level (jaw crusher and cone crusher) or the load at the rocker and rotor as well as the motor utilization (impact crusher).

Independently of this, the CFS regulates the frequency of the vibrating feeder and prescreen. A backlog on the prescreen is thus avoided and crusher utilization is optimized. When the crushing chamber is free again after overloading, material transport is continued without a delay.

The CFS facilitates the work of the operator because the machine automatically guarantees a homogeneous material flow, thus ensuring optimum loading of the crusher.