John Deere 460 P-Tier Articulated Dump Truck

| Make | John Deere |

| Model | 460 P-Tier |

| Type | Articulated Dump Trucks |

How can we help?

Description

- Net Power: 359 kW (481 hp) at 1,700 rpm

- Rated Payload: 41 820 kg (92,197 lb.)

- Heaped Capacity: 25.2 m3 (32.9 cu. yd.)

Models

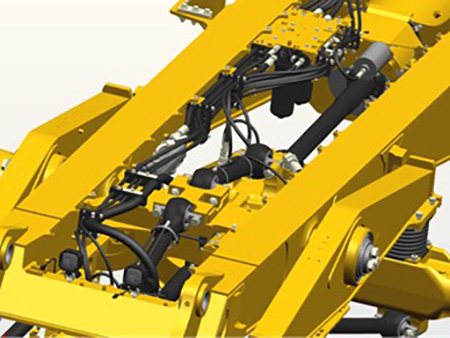

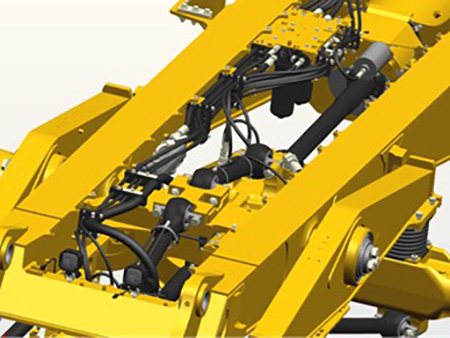

Redesigned electrical and hydraulic systems

Rendering of the updated routings

Rendering of the updated routings

Overview

Enhanced reliability with updated machine sensors and improved routing of both hydraulic hoses and electrical harnesses. Lighter and more fuel efficient while beefing up reliability with more robust sensors and simplified hydraulic and electrical routing compared to E-Series. Roadbuilding and Aggregate customers will find the updated routings highly valuable for its increased uptime.

Benefits

- Improved electrical and hydraulic system routings reduces hose length and number of connections — 10 percent fewer than E-Series models — to minimize potential leak points, fittings, and hose friction points

New Drive Modes

New Drive Modes (Normal, Eco, and Traction)

New Drive Modes (Normal, Eco, and Traction)

Overview

Available on 410 P and 460 P models, three new drive modes allow the operator to adapt to their situations and enhance the abilities of the ADT to fit their applications. These new drive modes optimize features such as the automatic differential-lock system to reduce tire wear, improve traction in soft conditions, and reduce axle wear by automatically applying only when needed. Customers will find the new drive modes highly valuable for their ease of use, uptime, and ride quality.

Benefits

- Normal: For typical operation and performance similar to E-Series ADTs

- Eco: When conditions allow, helps reduce fuel consumption by smoothing throttle input, reducing maximum rpm, and optimizing transmission response for those conditions

- Traction: Enhances the ability of the ADT to maintain traction in soft and slippery underfoot conditions by applying additional control to the automated differential-lock system and powertrain

Standard Onboard Features to Help Ease Operation

Operator settings in the monitor

Operator settings in the monitor

Overview

There are multiple owner and operator settings for features available in the monitor. Intuitive to use and easy to adjust, these features eliminate some of the operator inputs, allowing them to focus on more on moving more material efficiently. The best part is that all these features are standard on John Deere ADTs.

Benefits

- Rollover protection - Alerts the operator to a potential unsafe dump angle and stops the dump cycle. Set at 15 percent from the factory this setting can also be user defined by accessing the owner setting in the monitor.

- Downhill dump protection - Automatically calculates the truck position to make sure the dump body doesn’t travel over-center when dumping downhill.

- Auto dump brake - With auto dump brake enabled and driveline assist active, the service brakes will latch when unloading the machine.

- Hill hold - When stopping on an uphill slope, the truck will automatically keep the service brakes applied while the operator moves their foot from the brake pedal to the throttle to keep the truck from rolling backward.

- Frame protection - If a dump is stopped before material is shed out of the bin, the truck will cushion the bin travel back to cradle to prevent a full bin from aggressively seating onto the frame.

- Shuttle shifting - The transmission may be shifted direction without the truck coming to a stop improving cycle times and eliminating operator abuse

- Descent control - When activated by the operator, this setting will help automatically control the truck speed when driving down a descent through automatic use of the transmission retarder. Check decal on window for speed and gear limitations.

- Dump body limits - The maximum dump height can be restricted from full dump when working around low overhead obstacles.

- Transmission warm-up - At truck start up, the transmission will automatically begin a warm-up cycle. This improves not only ride and shift quality but also increases daily productivity by getting the transmission up to operating temperature quickly.

- Speed limits – Max speed limit can be set in the monitor to match jobsite conditions or site requirements, reducing complexity for the operator.

Improved Fuel Efficiency

Eco Mode

Eco Mode

Overview

Reduced weight combined with 3 drive modes on 410 P and 460 P deliver improved fuel efficiency over the E-Series.

Benefits

- Up to 7 percent* fuel savings compared to E-Series, regardless of drive mode

- Eco mode delivers up to 12 percent fuel savings compared to E-Series normal mode

- When conditions allow, eco drive mode helps reduce fuel consumption by smoothing throttle input, reducing maximum rpm, and optimizing transmission response for those conditions

Redesigned Dump Body

460 E-II dumping dirt into a pile

460 E-II dumping dirt into a pile

Overview

A completely redesigned dump body allows for improved material retention, lower loading height, lower center of gravity, and reduced transport width. Quarry and Aggregate customers will value the bin redesign and lower overall dump-body height (for easier loading and better material retention) for its increased uptime and cycle times.

Benefits

- Wider bin for better tire coverage and easier target while bench loading with an excavator

- New side-sheet design makes loading height the same from front to back

- Bin rail now features angled top, helping to reduce material spillage during travel

- Tailgate arms have been redesigned to maintain a transport width under 12 feet (460 E-II & 460 P-Tier -11 ft. 7 in.)

- Changes to the headboard offer increased coverage of the articulation joint

- Lower center of gravity to improve stability

- Uniform bin floor width improves ease of cleanout

Specifications

- CAPACITIES - Fuel Tank, ltr (gallons (US)): 609 (161)

- CAPACITIES - Heaped Capacity, m³ (yd³): 25.2 (32.9)

- CAPACITIES - Struck Capacity, m³ (yd³): 19.5 (25.5)

- DESCRIPTION - Air Conditioner: Yes

- DESCRIPTION - Fleet Management: Yes

- DESCRIPTION - Steering wheel adjustment: Fully Adjustable

- DESCRIPTION - Telematics Available: Yes

- DIMENSIONS - Approach Angle, Degrees: 26

- DIMENSIONS - Articulation Angle, ± Degrees: 45

- DIMENSIONS - Height - Max, mm (ft/in): 3890 (12 ft 9 in)

- DIMENSIONS - Hoist - Type: Twin, 1-Stage

- DIMENSIONS - Length - Overall, mm (ft/in): 10640 (34 ft 11 in)

- DIMENSIONS - Power Down: Yes

- DIMENSIONS - Turning Radius - Inside, mm (ft/in): 4630 (15 ft 2 in)

- DIMENSIONS - Turning Radius - Outside, mm (ft/in): 8900 (29 ft 2 in)

- DIMENSIONS - Turns lock to lock: 4

- DIMENSIONS - Width over Tires, mm (ft/in): 3410 (11 ft 2 in)

- DRIVELINE - Differential Lock: F: 100 / R: 100

- DRIVELINE - Displacement, ltr (Inches³): 13.5 (823.8)

- DRIVELINE - Emission Rating: Tier 4 / Stage IV

- DRIVELINE - Engine Manufacturer: John Deere

- DRIVELINE - Engine Model: PowerTech 6135

- DRIVELINE - Engine Output - Net, kW (hp): 359 (481)

- DRIVELINE - Final Drive: Planetary - Outboard

- DRIVELINE - Front Suspension: Nitrogen/Oil-Filled Struts - Auto Levelling

- DRIVELINE - Front Suspension - Type: Semi-Independent Leading A-Frame

- DRIVELINE - Parking Brake - Type: Disc - Transmission

- DRIVELINE - Rated Speed, rpm: 1700

- DRIVELINE - Rear Suspension: Rubber Suspension Blocks

- DRIVELINE - Rear Suspension - Type: Pivoting Walking Beam

- DRIVELINE - Retarder - Type: Hydraulic - Transmission

- DRIVELINE - Secondary Steering Type: Ground Driven Pump

- DRIVELINE - Service Brake - Actuation: Hydraulic

- DRIVELINE - Steering Type: Articulated

- DRIVELINE - Tire size - Standard: 29.5 R25

- DRIVELINE - Transmission Manufacturer: ZF

- DRIVELINE - Transmission Type: Countershaft

- PERFORMANCE - Gears - Forward / Reverse: 8F - 4R

- WEIGHTS - Gross Weight, kg (lbs): 73520 (162084)

- WEIGHTS - Net Weight, kg (lbs): 31700 (69886)

- WEIGHTS - Payload, kg (lbs): 41820 (92197)

Copy Set

Redesigned electrical and hydraulic systems

Rendering of the updated routings

Rendering of the updated routings

Overview

Enhanced reliability with updated machine sensors and improved routing of both hydraulic hoses and electrical harnesses. Lighter and more fuel efficient while beefing up reliability with more robust sensors and simplified hydraulic and electrical routing compared to E-Series. Roadbuilding and Aggregate customers will find the updated routings highly valuable for its increased uptime.

Benefits

- Improved electrical and hydraulic system routings reduces hose length and number of connections — 10 percent fewer than E-Series models — to minimize potential leak points, fittings, and hose friction points

New Drive Modes

New Drive Modes (Normal, Eco, and Traction)

New Drive Modes (Normal, Eco, and Traction)

Overview

Available on 410 P and 460 P models, three new drive modes allow the operator to adapt to their situations and enhance the abilities of the ADT to fit their applications. These new drive modes optimize features such as the automatic differential-lock system to reduce tire wear, improve traction in soft conditions, and reduce axle wear by automatically applying only when needed. Customers will find the new drive modes highly valuable for their ease of use, uptime, and ride quality.

Benefits

- Normal: For typical operation and performance similar to E-Series ADTs

- Eco: When conditions allow, helps reduce fuel consumption by smoothing throttle input, reducing maximum rpm, and optimizing transmission response for those conditions

- Traction: Enhances the ability of the ADT to maintain traction in soft and slippery underfoot conditions by applying additional control to the automated differential-lock system and powertrain

Standard Onboard Features to Help Ease Operation

Operator settings in the monitor

Operator settings in the monitor

Overview

There are multiple owner and operator settings for features available in the monitor. Intuitive to use and easy to adjust, these features eliminate some of the operator inputs, allowing them to focus on more on moving more material efficiently. The best part is that all these features are standard on John Deere ADTs.

Benefits

- Rollover protection - Alerts the operator to a potential unsafe dump angle and stops the dump cycle. Set at 15 percent from the factory this setting can also be user defined by accessing the owner setting in the monitor.

- Downhill dump protection - Automatically calculates the truck position to make sure the dump body doesn’t travel over-center when dumping downhill.

- Auto dump brake - With auto dump brake enabled and driveline assist active, the service brakes will latch when unloading the machine.

- Hill hold - When stopping on an uphill slope, the truck will automatically keep the service brakes applied while the operator moves their foot from the brake pedal to the throttle to keep the truck from rolling backward.

- Frame protection - If a dump is stopped before material is shed out of the bin, the truck will cushion the bin travel back to cradle to prevent a full bin from aggressively seating onto the frame.

- Shuttle shifting - The transmission may be shifted direction without the truck coming to a stop improving cycle times and eliminating operator abuse

- Descent control - When activated by the operator, this setting will help automatically control the truck speed when driving down a descent through automatic use of the transmission retarder. Check decal on window for speed and gear limitations.

- Dump body limits - The maximum dump height can be restricted from full dump when working around low overhead obstacles.

- Transmission warm-up - At truck start up, the transmission will automatically begin a warm-up cycle. This improves not only ride and shift quality but also increases daily productivity by getting the transmission up to operating temperature quickly.

- Speed limits – Max speed limit can be set in the monitor to match jobsite conditions or site requirements, reducing complexity for the operator.

Improved Fuel Efficiency

Eco Mode

Eco Mode

Overview

Reduced weight combined with 3 drive modes on 410 P and 460 P deliver improved fuel efficiency over the E-Series.

Benefits

- Up to 7 percent* fuel savings compared to E-Series, regardless of drive mode

- Eco mode delivers up to 12 percent fuel savings compared to E-Series normal mode

- When conditions allow, eco drive mode helps reduce fuel consumption by smoothing throttle input, reducing maximum rpm, and optimizing transmission response for those conditions

Redesigned Dump Body

460 E-II dumping dirt into a pile

460 E-II dumping dirt into a pile

Overview

A completely redesigned dump body allows for improved material retention, lower loading height, lower center of gravity, and reduced transport width. Quarry and Aggregate customers will value the bin redesign and lower overall dump-body height (for easier loading and better material retention) for its increased uptime and cycle times.

Benefits

- Wider bin for better tire coverage and easier target while bench loading with an excavator

- New side-sheet design makes loading height the same from front to back

- Bin rail now features angled top, helping to reduce material spillage during travel

- Tailgate arms have been redesigned to maintain a transport width under 12 feet (460 E-II & 460 P-Tier -11 ft. 7 in.)

- Changes to the headboard offer increased coverage of the articulation joint

- Lower center of gravity to improve stability

- Uniform bin floor width improves ease of cleanout